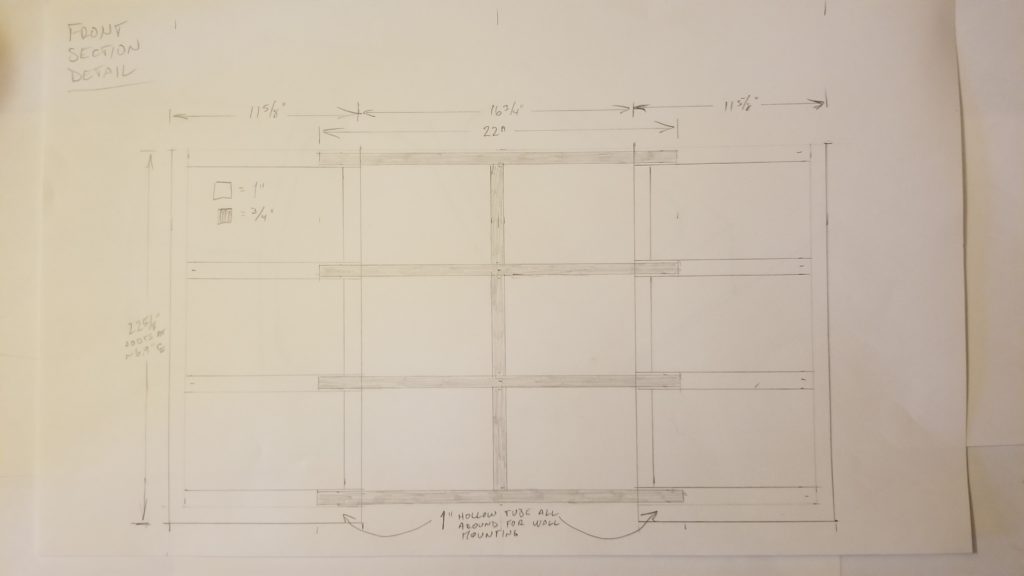

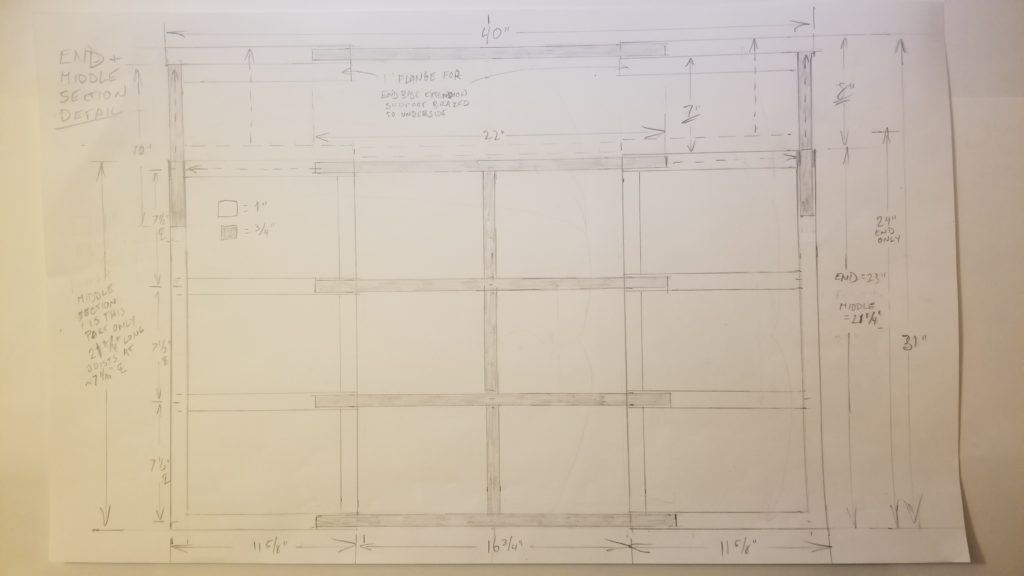

The design for the telescoping base sections is pretty much set per sketches above, although the exact dimensions have changed slightly.

- 100% aluminum framing: 1″ & 0.75″ square tubing for the frame & telescoping stringers, 0.75″ tubing for slide-out supports & u-shaped legs, 0.75″ plywood trim for support guiderails.

- The trailer box is a cube 24″ on all sides. Overall width of the trailer, from wheel nut to wheel nut, is 29″ (assuming max 1.5″W wheels) so it fits through my apartment door. If the wheels are larger and increase the width, I’ll have to jiggle it out sideways. That’s also the same width as my e-bike handlebars which are my gauge: if the handlebars fit through an opening, so does the trailer. Overall trailer length & height is slightly greater – 25.5″H x 24.75″L not including hitch – due to drop-down legs & support members of base sections.

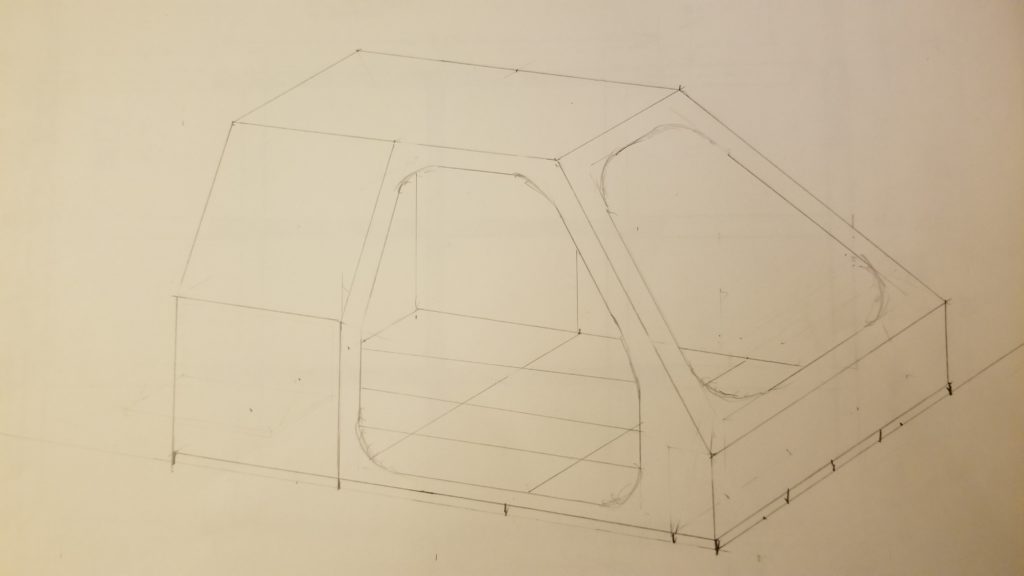

- Bottom, rear, and top sections are hinged and unfold to a camper base 66.5″ long + a 11″ pullout extension in the end section = 77.5″ overall length. The whole base assembly telescopes laterally 8″ on each side to expand the base to 40″ wide overall.

- Floor cladding will be made of 0.25″ plywood; finished with a nice reddish-brown stain outside & several coats of marine-grade urethane to complement the jet-black & brushed aluminum frame & body.

- Pullout extension in the end section has 2 removable snap-in floor panels that keep the pullout fully extended – 10″W x 19″L also of 0.25″ plywood with 10″H alu sidewalls.

- Sidewall cladding will be 0.02″ brushed aluminum sheeting. Sidewalls are 22″ tall on the front section, with a 10″H telescoping extension inside to close the gap between front & end sections on the side opposite the entry. This allows gear to be stowed the full length between the bedroll & sidewall without putting strain on the canopy.

- When expanded laterally in camper mode, rear wall gap is closed inside by a floating 18″W center panel. Has telescoping rails at bottom, middle & top for solid support (similar to the stringers in the base sections) so I can sit against it & lean on it on the inside.

- To ensure stability when unfolding the sections into camper mode, and and to remove stress on section hinges, base supports slide out on both sides from under the front section for the middle one, and from the middle section for the rear one. Base supports nest in-between flanges on their receiving sections to lock the 3 sections together when expanding/collapsing laterally.

- U-shaped legs hinge down from beneath each section – at 4 corners of front section + 2 rear corners of middle section + 2 rear corners of rear section. Legs are nested within the supports as above and drop out as the supports are extended.

- Canopy is made of 2.2oz waterproof ripstop, with screened entry & vent/window panels. See materials here.

- Canopy supports are sectional and made of 0.25-0.375″ fiberglass rods. Sections about 22″ long so they fit inside the 24″ cube, with flexible joints made with heat-shrink tubing like https://www.amazon.ca/s?k=heat+shrink+tubing&crid=2IGMLY2IKWLQ5&sprefix=heat+shrink+tubing%2Caps%2C410&ref=nb_sb_ss_ts-doa-p_1_18

- Need to work out some kind of spring mechanism for where the canopy supports connect to the base so they expand out automatically when the camper is opened, are sturdy enough to keep the supports extended in windy conditions and while unzipping entry/vents, and can be easily collapsed back into the trailer manually when the camper is closed. Will likely use torsion springs like these: https://www.amazon.com/Torsion-Spring-Deg-0-484OD-PK6/dp/B00VA0ON16 along with heat-shrink tubing & some kind of strapping/clamps.

- Zippered entry to the camper is on the side via the middle section as the canopy height will be greatest at that point: 44″.

- Canopy includes awning/vestibule on the entry side to provide rain shelter for lounging. Still need to work out the support design for this.

- Also need to still work out the wheel axle assemblies & hitch design. 😉